Asphalt Concrete: A Self-Repairing Road 24

Asphalt Concrete

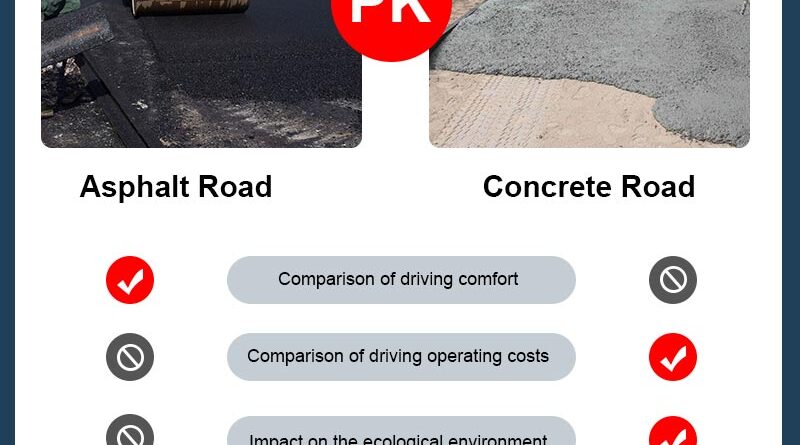

Considering its longevity, affordability, and convenience of use, asphalt concrete has been a mainstay in road building for many years. But conventional asphalt is not without its drawbacks, chief among which is its propensity to grow potholes and fractures with time as a result of environmental factors and traffic volume. Transportation disruptions, high maintenance costs, and higher expenses for governments and municipalities are the results of these problems.

Introducing a ground-breaking solution designed to solve these issues: self-healing asphalt concrete. The lifespan of road surfaces is greatly increased and maintenance expenses are decreased by self-healing asphalt, which uses cutting-edge materials and techniques to fix damage on its own.

The Concept of Self-Healing Asphalt Concrete

Microcapsules

The asphalt mix contains tiny capsules that are loaded with rejuvenating chemicals. These capsules burst open to release the healing ingredients that close the fractures and rebuild the pavement’s structure when they occur.

Induction Heating:

In this method, the asphalt mixture is mixed with electrically conducting fibers or particles. These particles become heated when an induction motor runs over the pavement; this softens the surrounding asphalt and allows it to seep into cracks, sealing them.

Bitumen Polymers:

Polymers with self-healing characteristics mixed with modified bitumen can be utilized. At high temperatures, these polymers can flow and seal fissures, keeping the pavement intact.

How does self-healing road technology work?

Road surface cracks and other small damages can be automatically repaired using self-healing technology, which uses cutting-edge materials and systems. Although particular techniques may differ, the basic idea is that implanted materials or healing agents are activated in reaction to harm. Some common self-healing processes function as follows:

Bio-Based Microcapsule Self-Healing:

During construction, tiny capsules containing a rejuvenating ingredient are inserted in the asphalt mix.These capsules rupture, releasing the healing ingredient, when traffic loads or environmental variables cause cracks to form in the pavement. In order to successfully seal the cracks and restore the integrity of the pavement, the healing agent seeps into them and forms a link with the surrounding asphalt.

Heating by Induction:

The asphalt mix is supplemented with fibers or particles that carry electricity, such as graphite or steel wool.A specialized induction heating unit is passed over the injured area when cracks appear.The conductive materials heat up when the machine creates an electric current in them.The surrounding asphalt becomes softer due to the heated components, and as a result, it flows into the cracks and solidifies to seal them.

Bitumen with Modified Polymers:

The binder used in asphalt, bitumen, is altered with polymers that have the ability to mend themselves. When asphalt is exposed to high temperatures—such as in the summer or during external heating—these polymers can seep through and fill in fractures. By improving the asphalt’s resistance to fatigue and deformation, the polymer-modified bitumen improves the material’s overall mechanical qualities.

Follow our Digiknowledge.co.in page for the latest updates about technology, bikes, cars, sports, lifestyle, and many more.

What are the advantages of self-healing asphalt concrete?

Increased Lifespan: Due to its ability to continuously repair small problems, self-healing asphalt can greatly increase the lifespan of road surfaces by preventing the need for major repairs or total resurfacing.

Savings: Although the initial outlay might be greater, there will be significant long-term savings because there will be fewer regular repairs and maintenance required.

Minimal Traffic Interruptions: Reducing the number of maintenance projects means less interference with traffic, which lessens traffic and boosts safety on the roads.

Benefits for the Environment: Self-healing asphalt reduces trash production and carbon emissions by prolonging the life of road surfaces and lowering the need for regular repairs.

Enhanced Performance: Self-healing asphalt roads typically have smoother surfaces and fewer potholes, among other positive performance measures.

What are the disadvantages of self-healing asphalt concrete?

Greater Starting Expenses: Higher initial expenditures are incurred because self-healing asphalt uses more expensive ingredients and technologies than conventional asphalt.

The complexity of implementation can pose a challenge for certain communities, as the technology calls for certain knowledge and equipment to be installed and maintained.

Restricted Proven Track Record: Despite its potential, self-healing asphalt is still a relatively new technology, and there is a dearth of long-term performance information.

Technical challenges: It can be difficult to maintain the right balance between durability and flexibility and to ensure that self-healing chemicals are distributed uniformly.

Nations Using Asphalt with Self-Healing Technology

The following nations are leading the way in the development and application of self-healing asphalt technology:

The Netherlands is considered a pioneer in the field of self-healing asphalt technology. The application of induction heating and microcapsules in asphalt has been the subject of in-depth research at Delft University of Technology.

China: The Chinese are also currently investigating asphalt that can mend itself. Many academic institutions and research centers are creating and testing various self-healing techniques.

United States: Several studies and pilot programs are being conducted in the United States to assess the viability and effectiveness of self-healing asphalt in various climatic and traffic scenarios.

United Kingdom: On its road network, the UK has started testing self-healing asphalt through programs. Collaboration between academic institutions and industrial stakeholders is one example of this.

France: In an effort to provide environmentally friendly infrastructure solutions, France is looking into the use of self-healing asphalt.

Conclusion

With the potential to improve road surface longevity and durability while lowering maintenance costs and environmental effects, self-healing asphalt concrete is a significant technological achievement in road building. The long-term advantages of this choice for modern infrastructure construction outweigh its drawbacks, which include greater initial expenditures and more difficult execution.

As more countries embrace this technology and research advances, self-healing asphalt has the potential to become the norm in road building, resulting in more robust and sustainable global transportation networks.

What is self-healing asphalt concrete?

By adding unique materials and technology, such as microcapsules containing healing agents, conductive fibers for induction heating, or polymers with self-healing capabilities, self-healing asphalt concrete is a kind of asphalt intended to mend minor problems on its own.

How long does self-healing asphalt last compared to traditional asphalt?

The lifespan extension of self-healing asphalt is contingent upon a number of parameters, including traffic volume and environmental conditions, although it can potentially withstand much longer traffic than conventional asphalt by continuously mending small defects.

Can existing roads be retrofitted with self-healing asphalt?

It can be difficult and not necessarily possible to retrofit self-healing asphalt onto existing roadways. In general, significant resurfacing projects or new road construction are better places to use self-healing technology.

What kind of maintenance does self-healing asphalt require?

When it comes to maintenance, self-healing asphalt needs less frequent attention than conventional asphalt. To make sure the self-healing systems are operating as planned, periodic inspections are required to monitor their functionality.

How does self-healing asphalt contribute to sustainability?

Self-healing asphalt reduces the need for raw materials and energy, lowers carbon emissions, and minimizes waste creation by prolonging the life of roads and lowering the frequency of repairs. This helps to promote overall infrastructure sustainability.

How long will it take before vehicles can drive on the new surface?

This varies according to the work. You should give the new lot a full day to cure after asphalt resurfacing, depending on the day’s temperature. Following completion of the procedure, sealcoating usually requires a 24-hour drying (curing) period.

How long does asphalt concrete last?

Proper care and upkeep are the most important factors in increasing the life of asphalt pavement. The typical lifespan of well maintained asphalt pavement is 25 years, but it can endure up to 30 years.

.